Design Phase of the DDDAC1794 NOS solution

The checklist for the new design...

As my wish list for the new design was now finalized, I wanted to take the following steps:

- Work out the theory of operation to do "no digital filter" mode and design DAC and logic around it

- Create a bread board with two PCM1794 for testing

- How to do the NOS (no digital filter) Mode

- How to generate maximum output versus minimum distortion

- How to make the Data signal -Right Justified/24 bits- out of -I2S Data-

- How to proper bias the PCM1794

- Start listening tests and select best methods for:

- Influence of local power supply filtering

- Compare digital Filter against NOS Mode (to be sure ;-)

- Design PCBs for the Mainboard and DAC module

- Design a power supply for 5 Volt and 12 Volt

- obtain several USB receivers to do listening tests and select the best

You can download the full schematics (USB mainboard version) from the download section or push the button below:

NEW: I have been building a version with additional SPDIF input (based on WM8804)This is available as kit (of course ;-)

I updated my website now and you follow the link at the right hand site (S/PDIF Input) below the USB button.

I also rationalized the DAC PCB Boards as well the power supply PCB. The revised schematics are in this as well. So I highly recommend that

you download this document as well:

Theory of operation to do "no digital filter"

Before I made the choice to use the PCM1794, I already knew this particular chip had an option to avoid the built in digital filter.

Reading the datasheet is extremely confusing, but one thing stood out. You cannot use I2S signals, but instead the format must be right justified 24 bit.

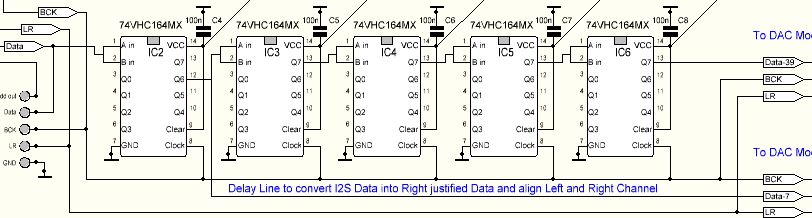

Well that is no big issue, as the I2S Data signal is basically the same, only time shifted. So you need a simple shift register to delay the data on 7 clock cycles

(32 bit word - 24 bit minus one (as I2S is delayed already one clock cycle). As the PCM1794 works in mono mode when the no digital filter mode is selected

you need an extra delay of 32 bits to synchronize the Left and Right signal. I have seen many designs who forgot about this. May be you cannot hear it,

but what the heck, it is just a few chips more and you do copy and paste when designing the PCB ;-) Below is a part of the circuit (have you downloaded it already?)

which shows the principle of the delay logic

The datasheet is telling you, that in no digital filter mode, the word clock needs to be 1/4 to 1/8 of Fs.... How on earth to do this without complex

logic and or processors? I almost gave up, till I finally started to get an idea why this was! Only to keep the whole clocking system inside the chip locked in so to speak.

For this reason the system clock is used, which normally is 4 times BCK (the bit clock of the digital data). A logical thought was to reduce the System Clock (SCK) by 4

and the whole thing must be ok than. And then the final spark.... BCK is actually 1/4 of SCK, so why not connect BCK to the SCK input? This is against ALL LOGIC and seems to be

definitively not supported by the datasheet...... BUT ..... it works perfectly :-) What a throw, instead of tons of CPU and glue logic stuff, just connect SCK to BCK, haha !!

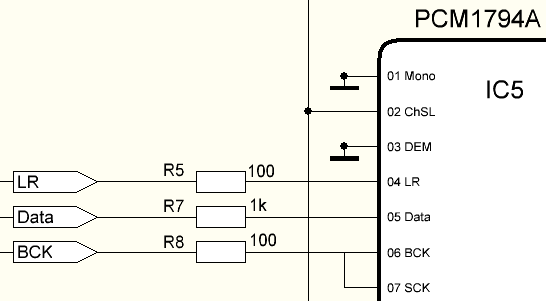

Just a small note on why the data line has a 1kOhm decouple resistor, where the others have a 100 Ohm one... Well, simple minds find simple solutions ;-) The 100 Ohm ones

are to decouple the digital domains. Good practice in digital design, so very standard stuff. The 1k however is larger than normal and with the Input capacitance from the DAC

input, it creates a small delay (RC time) which is needed to align for the lost 1/2 clock cycle in the shift register..... Others do this with D Flip Flops or even more

complex solutions. Well, a different value (only that) of a resistor does the job also!

Now I found out the real trick, I could finally start to do the real work..... design a working DAC

|

The very first Prototype

In Ebay I bought a couple of PCM1794 on a DIP28 board, so it was easy to work around. Using a digital oscilloscope and a logic analyzer

I have been able to measure, test and debug all possible situations. Without, there is no way, you can bring this to a good end. A good investment!

I could now build up the circuits I described above and was not happy with the delay times of the 74HC164. It worked, but the clock and data were so close

I was afraid, that even another batch of chips might cause problems if someone would decide to build my design: NOT acceptable of course...

So I decided to use the 74VHC164 versions, which comes only in SMD package. In the end a good decision, as delays were low enough to nicely line up signals

The most time (and DAC Chip ;-) consuming part proved to be finding the right biasing and optimum passive I/V conversion...

|

The first Prototype

This is a great way of designing circuits; easy plugging around parts with different values etc. Quick testing, quick listening...

|

Finding the optimum Bias and Output Voltage

Indeed a very tricky business... I quickly found out, that there is no real correlation between the reference resistor value (at pin 20) and the output current.

The output current at zero signal level is of course resulting in the output DC voltage, which again is important for the maximum output signal

which should not clip against ground and the positive supply voltage. One thing was clear, the higher the analog supply voltage, the more headroom

for the DAC internal current sources. The datasheet tells us, that the maximum Vcc (analog supply) is 6,5 Volt. Oh really? This is just a current source, hard to believe

after my experience with the TDA1543, that this is really the maximum. This is the most easy test... Play music, connect the VCC to a LAB power supply and slowly increase the

supply voltage. Measure the supply current and wait till it SMOKES :-) Believe it or not, the Chip worked fine till 10 Volts. It smoked at 11 Volts. I also found out

by several test, that there was a kind of maximum, in such way, that there was no improvement in headroom, which was like round 8,5 Volt.

Therefore I decided that 8 volt would be a great compromise.

I learned, that the following was the optimal situation

- Vcc 8 Volt

- R ref 6,1KOhm

- R Load 270 Ohm, resulting in a Bias of 2,72 Volt

- Current Output at zero signal ~ 10mA allowing headroom for full scale current (6,3mA)

- Full scale voltage swings between 1,0V and 4,4V (4,5V is max before clipping)

- Full scale voltage RMS therefore 1,2V RMS

- d2 and d3 below 0,2%, which is very good for passive I/V

Tweaking the second prototype by use of listening sessions

The clever reader of course noticed that the first prototype could never have been used for listening tests, as one PCM1794 chip in NOS mode is just MONO.

I also wanted to make sure that the real prototype we would listen to would be as close as possible to the final (PCB) version. On the picture you see the two DAC chips

and the power supplies for the analog and digital section. The listening tests made one thing VERY clear. The difference between with / without digital filter

is so clear, you listen to it a few times and say, check in the box, we now know NOS is the way to go. More focus, more dynamic, extremely clear direct sound :-) The old curtain pulled away story...

Then we tested the impact of using decouple and capacitors and inductors in the analog and digital section. To be honest, no BIG differences, but audible.

And the end result was surprising: In the analog sections the double use of an inductor and capacitor (LC filter) smoothed up things very nicely, BUT in the digital section it was

no improvement at all, on the contrary, the sound was getting a bit dull.

|

|

Second (final) Prototype:

This prototype (VERY close to the PCB versions) was used to do intensive listening tests and test some ideas

|

So final conclusion it was VERY good that we tried all this stuff and not used pure theory to come to the best design ;-)

For the power supplies around the chips, I used the low drop LF series. Very low noise and they sounded a trifle better than the LM317 or UA78xx series. The low drop

allowed for extra RC and LC filtering, so a WIN-WIN situation....

|

Of course I wanted to design some nice PCB's again

It is not only the PCB itself I needed to design. Actually that is the easier part. I also wanted to make to sure there is a real CONCEPT behind

how to enable paralleling DACs. I will spare you all the other ideas I had initially, so let's jump to the final solution.

A Mainboard which accepts multiple DAC Modules.... At the left you see the final result. I kept lines as short as possible

and made sure there is an easy to use connection for the WaveIO Modules at one side. On the other side I wanted to have

the opportunity to use multiple resistors to obtain the correct R Load (passive I/O remember?) by paralleling different

values. In the middle is the DECK concept. By using the hex-spacers, you can easily stack the modules and connect them

by putting a wire from top to bottom through the holes. Which are nicely aligned by the way ;-)

The RED color is not needed, but I thought it was quite fashionable! The quality of the board is beyond any doubt and to avoid any oxidation

or poor connections, I decided to make GOLD plated boards this time.

More details and pictures how this works is in the next part of the story; the construction...

|

PCB for the Mainboard:

This board is used to connect the outside world to the DAC and also to carry the DAC Modules, which can be stacked for parallel use :-)

All SMD parts are assembled upfront.

|

And here is the dark force :-)

There are two reasons for the black color; there is quite some power consumption on the board (every board takes 100mA, so dissipates

like 1,2 Watt) so I wanted to make sure there is optimum heat spread and dissipation. The second one is, that it looked nice on the RED Mainboard ;-)

Also this board is gold plated and has a very effective layout (I must say...) Also important is the separation between both channels

as well the separation between digital and analog sections. I also added (as there was space left...) more capacitors on the board for supply

decoupling and filtering. Indeed all this measures resulted in an increased audible performance versus the second prototype,

which of course has poor layout and had less filtering.

|

|

PCB for the DAC Module:

I call this a deck as well, as they stack so nicely :-) The SMD parts are assembled by a professional SMD assembly company...

Especially the mini-SOP is almost impossible to solder yourself...

|

|

Input = Output

Nice saying, but here it is true.... The DAC can be the best in the world ( ;-) ) but if there is an issue at the input side of things

you will never reach the maximum potential... Before pinning my design on an USB Receiver, I wanted to make sure I picked the one with the best sound...

Actually there are many solutions on the market, but I decided to pick only 4:

- The HiFace module (based on the M2Tech)

- Rockna Audio, similar to the HiFace board, but simpler design

- The Musiland Monitor 03

- The WaveIO Module (from Lucian Luckit) link to his Site

Long story short, you listen to a few soundtracks and things are so clear, the WaveIO wins easily.

Sound stage is more transparent, you can look through easier. Also texture of voices and instruments are more natural.

On top, when you use a high end 5V power supply (instead of USB bus powered mode) all this improves another clear step.

You will read more about this in the [Power Supplies] and [Sound Check] sections.

|

WaveIO USB Receiver:

Clearly number ONE among the boards I used. Lucian has a real eye for small details. Well DONE!

|

Lucian did a great job designing this receiver and we agreed he would make a special version for the DDDAC. No big things, but we left out

the spdif for example and some other things you do not need when you build my design. On top, the drivers and ID's are recognized as DDDAC. So it is more

consistent in your audio player. I am very glad I found this solution and many thanks go to Rumania!!!

PS: what I like, is the fact the board can be easily switched between bus powered and external powered. Great for initial testing :-).

Also both options have on board filtering!

Keep reading ...... the story continuous with a detailed circuit description ( circuit description )

Or skip this technical stuff and go directly to the construction ( Construction ;-)

|